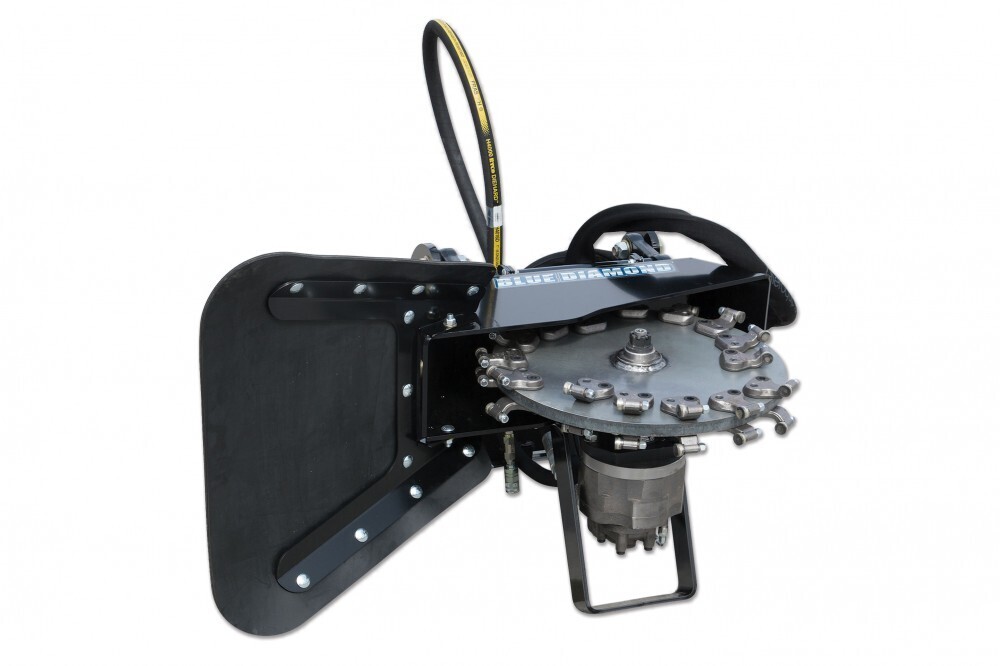

Extreme Duty Stump Grinder

Posted on: December 19, 2023

KNOXVILLE, Tenn – Blue Diamond® Attachments decided after a number of years to upgrade the stump grinder they currently offered. The new model would be highly efficient and effective. With many options are available on the market today, yet it seems most customers are not happy with what they have.

This new model features a radial pistol motor that can produce incredible amounts of torque. On a skid steer, you have limited amount of hydraulic HP so you must capture everything possible to produce effective results. The industry standard of using rotor type or roller gear type motors has proved to be about 70% efficient where the radial piston motor is running about 94% efficient! The piston motor also maintains its torque through its flow range better and therefore it does not require the machine to be at full RPM all the time. The current units on the market turn very slowly to gain torque.

Customers also told us that cutting in one direction was not efficient and they wished they could cut while going in forward and in reverse. We have accomplished this by using a torsion cushion system that keeps the cutting wheel perpendicular while grinding in either direction. This also prevents from stalling out when accidentally moving the host machine too quickly.

The cutting wheel size is a 24" diameter on the low flow models and the high flow models will have a 26" wheel. Both models will have teeth on both sides for bi-directional cutting. We now feel confident that this upgraded stump grinder will be the one that serious tree companies will rely on. We also feel that if you are going to grind any reasonable amount of stumps a year, this unit will be worth paying a little more for to save wasted time, fuel, and unnecessary wear on your host machine.

###